In the world of packaging, an efficient motor can be the difference between a productive line and a costly bottleneck. Among the various drives used, the gear motor stands out for its compact size, high torque output, and simple integration. This article walks through the key selection points and calculation methods that ensure you choose the right gear motor for your packaging equipment, all while keeping the language clear and engaging.

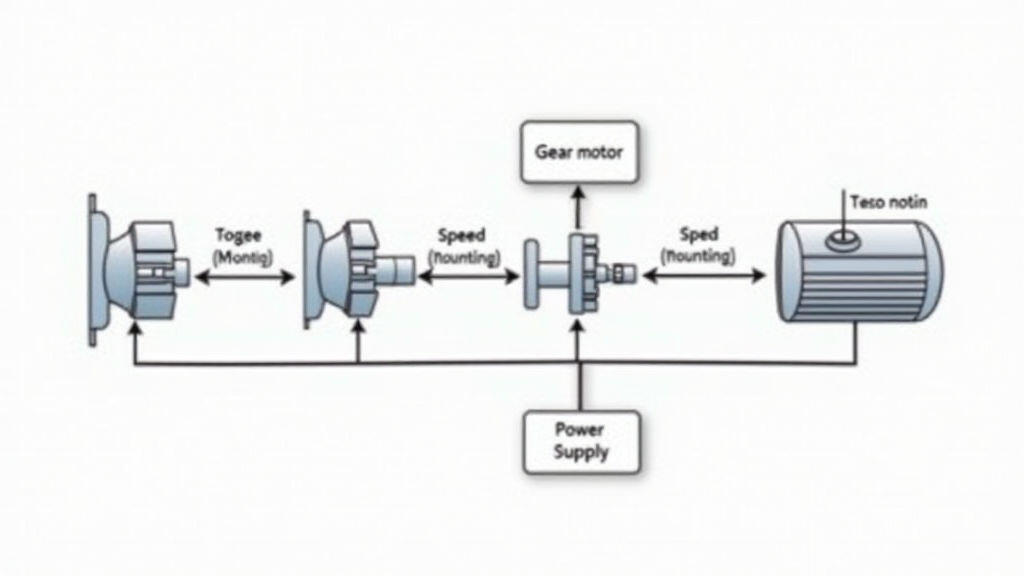

Packaging machines—be they carton fillers, blister pack assemblers, or palletizers—often need to deliver steady torque at moderate speeds. A gear motor combines a high‑torque wound rotor with a gear head, delivering power directly to the machine’s load. This eliminates the need for separate gearboxes or complex drives, reducing maintenance and improving reliability.

Start by quantifying the load that the gear motor must drive. Ask yourself:

For instance, a carton sealing machine might experience a peak torque of 25 N·m during sealing but only 5 N·m during feed. This variability must be captured in the motor’s duty rating.

Gear motors come in fixed shaft speeds (e.g., 100 rpm, 200 rpm). Measure the speed the machine’s output shaft requires:

Knowing the acceptable speed margin (±5 %) helps you pick a motor whose nominal speed matches the load while leaving room for thermal variation.

Packaging lines are usually dense; physical space limits motor placement:

These parameters are critical, especially when retrofitting older machines or in high‑density automation cells.

Electrical sizing is straightforward:

Remember that many gear motors labelled “extra‑high torque” have an inbuilt rectifier, eliminating the need for an external supply transformer.

Long service life and low downtime are essential in packaging. Choose motors with:

Once you have the above data, the math is a two‑step process: torque calculation and power calculation.

The starting torque required (Tstart) can be estimated with:

Tstart = (Load moment) + (Acceleration moment)

where the acceleration moment is Mass × Acceleration / Gear Ratio. Summarize this with a tolerance factor (e.g., 1.2 × Tstart) to assure you are not under‑estimating.

Power (P) is torque times angular speed (ω):

P = T × ω / 1000 = T (N·m) × 2π × Speed (rpm) / 60 / 1000 (in kW). Add a safety margin for heat dissipation—again, 10–20 % is typical.

Suppose a palletizer needs 20 N·m at 120 rpm. - ω = 2π × 120 / 60 = 12.57 rad/s - P = 20 × 12.57 / 1000 ≈ 0.251 kW. With a 15 % margin: choose a 0.3 kW motor. The gear ratio often kills the motor’s speed to 100‑rpm interval, making a 0.3 kW gear motor a perfect match.

Most modern packaging equipment uses a PLC or DCS to supervise motor performance. Ensure the gear motor’s on‑board VFD (variable frequency drive) or speed controller is compatible. If the motor lacks internal drive, you’ll need an external VFD that matches the motor’s voltage and current rating. The benefit? You can fine‑tune speed curves to reduce torque spikes, saving wear and power.

The packaging sector is shifting toward digital twins and predictive maintenance. Modern gear motors now embed sensors that report temperature, vibration, and load. By feeding this data back to a central system, operators can catch abnormal behavior before it leads to a shutdown. As sustainability becomes a top priority, gear motors’ high efficiency and lower energy consumption make them increasingly attractive.

Choosing the right gear motor for packaging equipment boils down to a systematic understanding of load, speed, space, and electrical parameters. By applying straightforward torque and power calculations, you can identify a motor that delivers reliability, performance, and cost‑effectiveness. And as the industry moves toward smarter, data‑driven operations, these thoughtfully selected gear motors will form the backbone of next‑generation packaging lines, driving both productivity and sustainability.

Leave A Reply

Your email address will not be published. Required fiels are marked